The frame of the machine adopts No.50 square profile and national standard cold plate material. The chain is a 5-point stainless steel chain, uneasy to rust and the conveyor speed is adjustable. Adopts water cooling cycle to cool the mold. The uooer temperature is heated by spiral tube, with long working life and uneasy to damage. Intelligent PIDoutput control. which is stabel and accurate in temperature. The lower heating plate is processed by CNC grinding machine, with high plane precision and baking mold evenly.

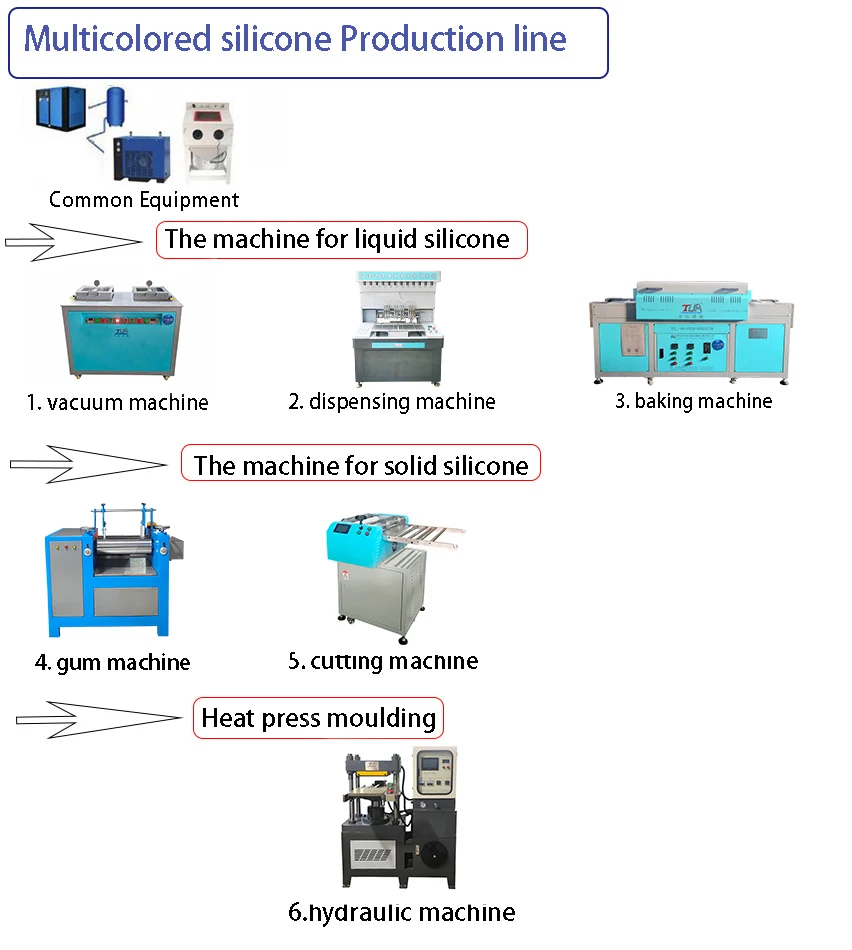

This machine can be used for baking the liquid silicone or pvc during the production. it have both heating function and also the cooling function. After baking, the machine will cool the mold to suitable temperature for the next process.

it can be apply for the production of pvc rubber slipper, multicolor silicone product and also the pvc shoe sole production. Convenient and high output.

seaworthy wooden case.

Seaworthy wooden case packing,To be packed by new strong wooden cases suitable for long distance ocean transportation and well protected against dampness, moisture, shock, rust and rough handling.

Send to domestic

Pre-sale service:

1.We offer the mechanical parameters and the analysis of the machine for you.

2.You may obtain the ex-factory price of the machine.

3.Welcome to visit our factory and training.

4.We can offer all the things you need in the processing, like: the mold, material, machine, technology.

After-sale service:

1.Send technicians abroad maintenance.

2.Free training service.

3.24hours and whole year service without vacation.

4.We will set files for the old and new machine, and provide service for the hydraulic machine of other factory.

5.All sold machine will be provided with warranty of one year.

6.free warranty of one year ,and maintenance all life of machine, and the service will be provided in your company. If you meet with any problem about the machine.

1.Q: Are you a factory or trading company?

A: We are a factory.

2.Q: Where is your factory located?

A:The town of Dalingshan, dongguan city, guangdong province, China

3. Q: How about quality control in your factory?

A: focuses on quality,quality control from beginning to the end. Every piece of goods is tested strictly before packing and delivery.

4.Q: How about guarantee ?

A: One year guarantee.

5.Q:Can you provide technical support?

A: Selection to provide comprehensive technical support, and technical training.

6. Q:Why choose Jinyu Automation Equipment Co.,Ltd.?

Research and development, patent products, company's mission: to help customers improve production efficiency and reduce labor costs