Another silicone vacuum press hydraulic machine packed by our workmate, this machine is going send to the customer of another country.

The packing view:

The feature of this vacuum press machine:

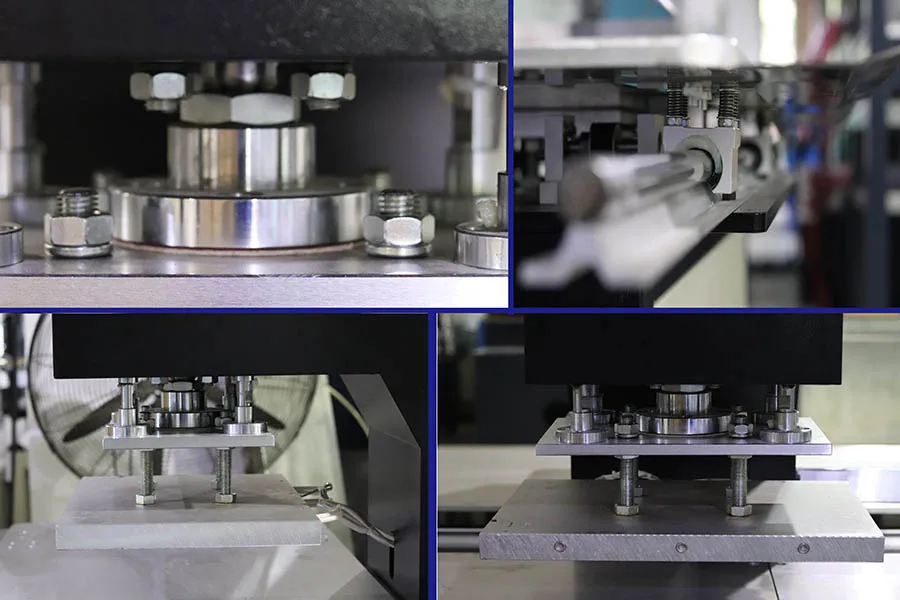

1. Stable structure: it adopts the classic 4-column and 3-beam structure, the medium carbon steel is thickened on the upper seat and the thickened and hardened columns ensure the structure is stable.

2. With a vacuum pump: before pressing the material, vacuum pump get work and get out of the air form material, which is convenient and make sure there are no bubble in the product.

3. Precision clamping: using technical plane pressure equalization correction, maximum pressure(200Kg) nut leveling device, can increase the parallelism of the upper and lower heating plates to 0.05mm.

4. Precise temperature control: adjustable from room temperture to 400℃,using intelligent temperature control the temperature fluctuation range within ±2℃

5. Easy to operate: PLC combined with touch screen, whether it is debugging or production can be operated directly and easily.

6. Easy to adjust the pressure: there is a botton below the PLC screen and you can adjust the adjust the pressing pressure by hand easily and visually, which is convenient when you want to press some flexible pattern, like cotton and the pad.

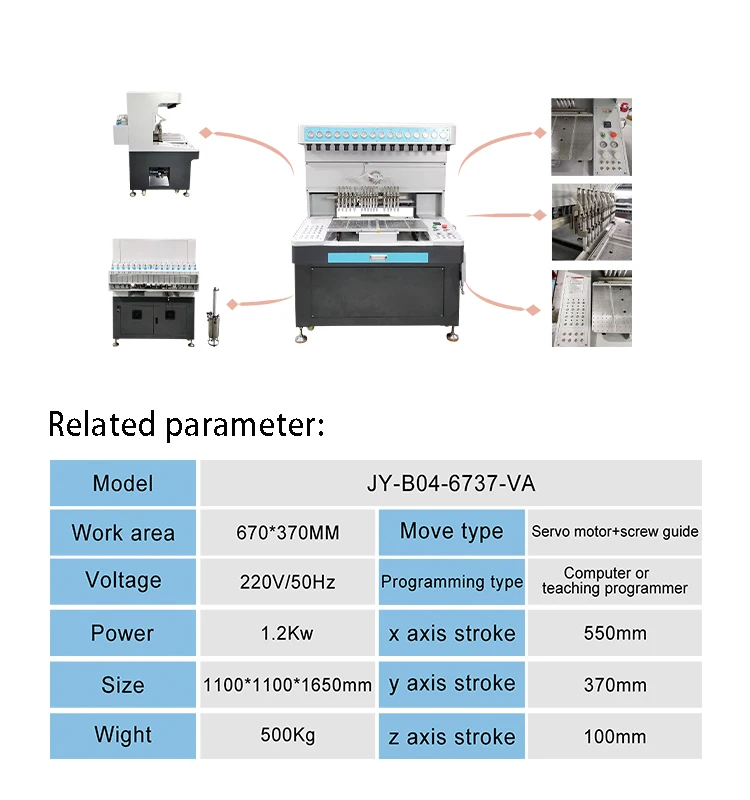

Related parameters:

|

Model

|

JY-A02C

|

|

Worktable size

|

400*400mm

|

|

Total pwer

|

17.8Kw

|

|

Voltage

|

380V, 3 phase

|

|

Size

|

1350*1750*1850mm

|

|

Maximum pressure

|

63T

|

|

Maximum temperature

|

400℃

|

|

Main cylinder diameter

|

200mm

|

|

Main cylinder stroke

|

250mm

|

|

Vacuum pump power

|

1.5Kw

|

What can we do with this machine:

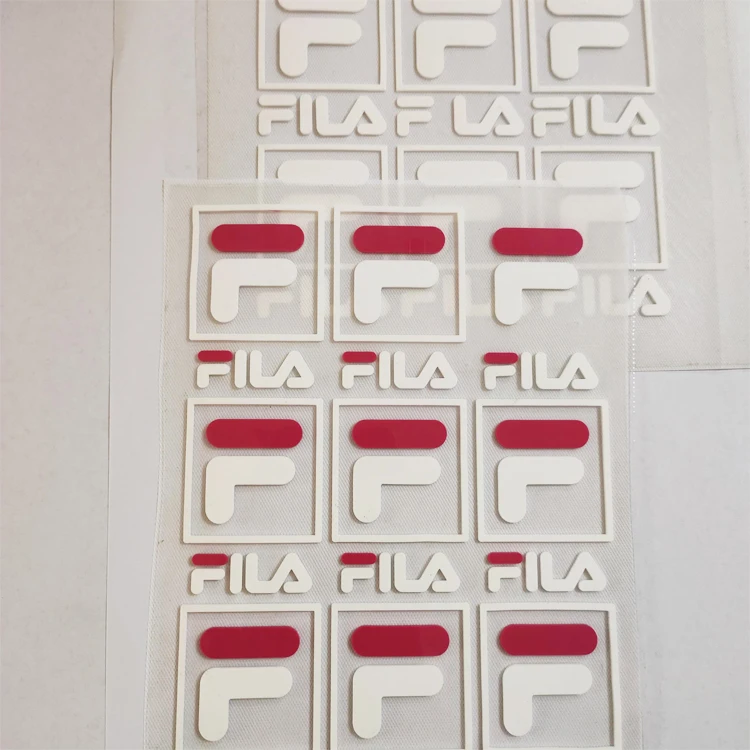

All kinds of silicone heat transfer/thermal label, you can make colored and customized label with this machine.

These finished label can be used in embossing on fabric, jeans and so on. Just like the picture shows.

With vacuum pump, it can vacuum silicone material before heat pressing it, which make this machine widely used in silicone doll, electronic accessories and so on.

Our company has its own factory, the staff have many years of production engineering technical experience, the overall production strength, the machine quality is high.At present, our r&d department often develops new machines according to market changes. Strive for the market for customers.High production speed and guarantee.Independent research and development, multiple patents.Be flexible in order to see specific products.

Our Services

Pre-sale service:

1.We offer the mechanical parameters and the analysis of the machine for you.

2.You may obtain the ex-factory price of the machine.

3.Welcome to visit our factory and training.

4.We can offer all the things you need in the processing, like: the mold, material, machine, technology.

After-sale service:

1.Send technicians abroad maintenance.

2.Free training service.

3.24hours and whole year service without vacation.

4.We will set files for the old and new machine, and provide service for the hydraulic machine of other factory.

5.All sold machine will be provided with warranty of one year.

6.free warranty of one year ,and maintenance all life of machine, and the service will be provided in your company. If you meet with any problem about the machine.

Any other questions for us:

1.Q: Are you a factory or trading company?

A: We are a factory.

2.Q: Where is your factory located?

A:The town of Dalingshan, dongguan city, guangdong province, China

3. Q: How about quality control in your factory?

A: focuses on quality,quality control from beginning to the end. Every piece of goods is tested strictly before packing and delivery.

4.Q: How about guarantee ?

A: One year guarantee.

5.Q:Can you provide technical support?

A: Selection to provide comprehensive technical support, and technical training.

6. Q:Why choose Jinyu Automation Equipment Co.,Ltd.?

Research and development, patent products, company's mission: to help customers improve production efficiency and reduce labor costs