We are a machine factory in Dongguan city of china, we produce Silicone machines, PVC machines, KPU shoe machines, such as liquid pvc dripping machine, silicone sticker making machine, injection mold machine, hydraulic press machine, rubber vulcanizing machine, Fabric 3D silicone emboss machine, Heat transfer label machine, and other related machines. if you need more detail, please contact Jinyu Machinery: email: jinyumachine@hotmail.com WeChat: +86-13829130058

Thursday, December 29, 2022

Tuesday, December 27, 2022

Sunday, December 18, 2022

Thursday, December 8, 2022

Tuesday, December 6, 2022

Saturday, November 26, 2022

Sunday, November 20, 2022

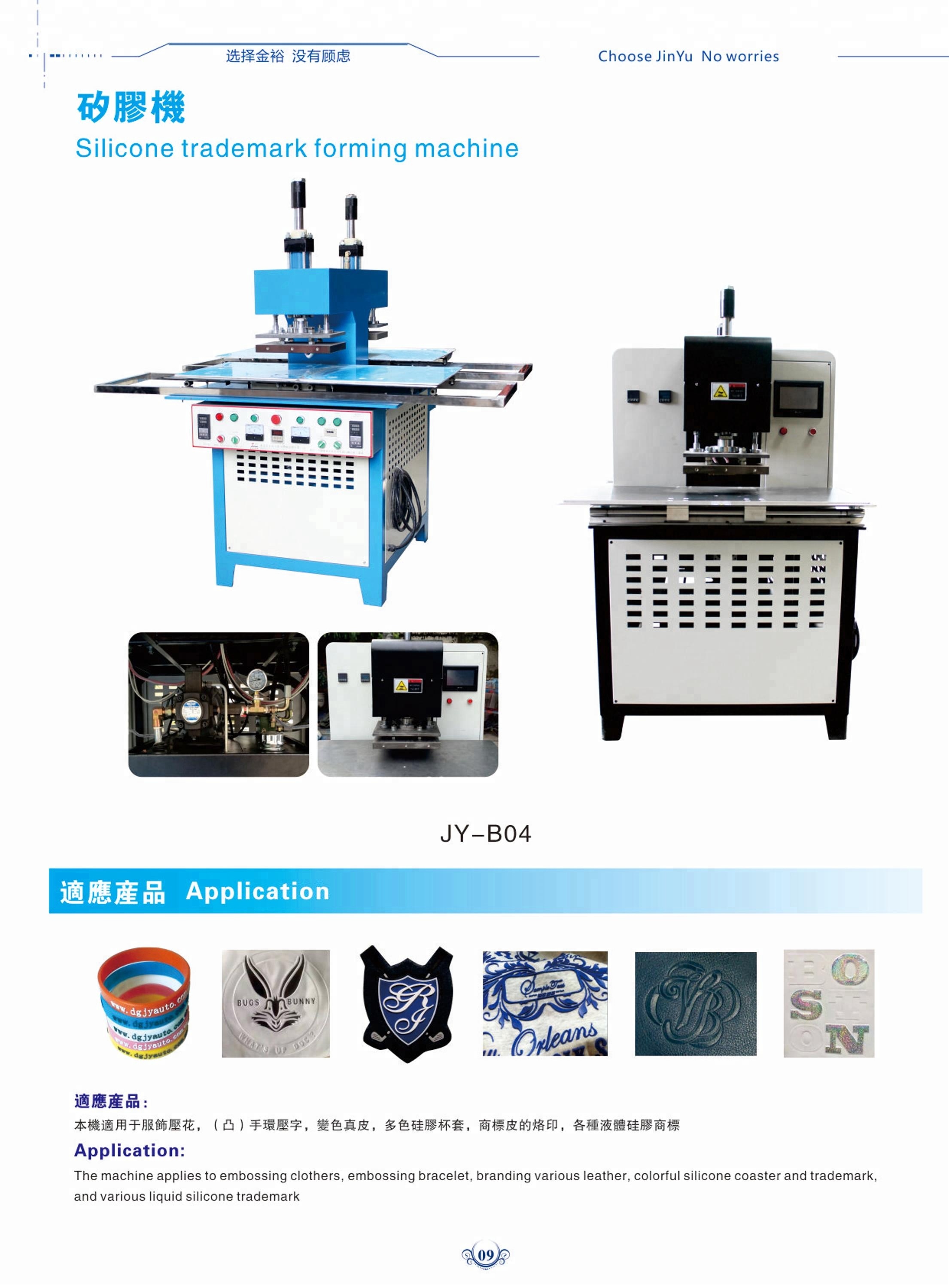

How much knowledge of embossing machine do you know?

Jinyu machinery has been in the industry of the embossing machine for 20 years, and its products are spread all over the country :India, Pakistan, Mexico, South America and many other countries and regions.The products are well received by the customers at home and abroad. Jinyu machinery is constantly improving and developing new embossing equipment, insisting on leading the technology and making efforts to create the core products with independent intellectual property rights.So,I'll tell you about the knowledge of embossing

Embossing machine alias: glue machine, silicone machine, printing machine, hot pressing machine, silicon rubber embossing machine.

Working principle:The raw material used is liquid silicone and liquid PVC .By dropping the glue to the mold, the material is directly covered with the cloth on the mold, then the cooling is made after adding the temperature, the time can be set in advance, the operation is simple, the equipment structure is compact and the oil pressure pressure is used, the performance is stable and safe, and the adhesive force of the product is strong.

advantage :

1. Self counting function, automatic statistics of the number of die.

2. The temperature is up and down, and the temperature is adjustable at 0-400 degrees centigrade. The intelligent temperature control makes the setting temperature difference from the actual temperature by + 1 degrees Celsius.

3. The double position of the embossing machine adopts double oil pumps, and the oil pressure is pressed, and the pressure is stable. Double working position at the same time does not affect the working speed and pressure of both sides. And the embossing machine can be customized according to the customer's needs.

Type:

1. automatic embossing machine

2. Standard embossing machine

3. Finished clothing embossing machine

Wednesday, November 16, 2022

1. How to clean the dispensing machine ?

When the dispensing machine point material, whether you point is silicone or PVC, in the day when the dispensing machine must be paid attention to cleaning this link, it is not missing, it is said that the cleaning machine is the link, the top of the dispensing machine is self cleaning function, white oil is the best choice of cleaning. If there is no silicone raw material on the same day, keep it fresh in the fridge and continue to use it for second days. It doesn't matter if you don't put it in the fridge if it's PVC raw material.

2. What is the best method for raw material filtration?

Some customers said that the needle of the dispensing machine would be blocked. The reason is that the raw material is not filtered clean. I have a good idea: when you pour raw materials, you can add a filter to filter. If someone asks what kind of filtration is more suitable, we recommend a simple, affordable and easy to use -- stockings, no mistake is stockings!!! Silk stockings filter is also very convenient and practical. Clean and hygienic PVC (silica gel) material can ensure continuous and efficient production of dispensing machine.

Tuesday, November 15, 2022

Sunday, November 13, 2022

what is dispensing machine ?

Dispensing machine, also known as glue applicator, glue dispenser, glue machine, glue filling machine, etc., is specially designed to control the fluid. The automatic machine that drips and coats the fluid on the surface of the product or inside the product can realize three-dimensional and four-dimensional path dispensing, precise positioning, precise glue control, no wire drawing, no glue leakage, and no glue dripping. The glue dispenser is mainly used for the precise point, injection, coating and dripping of glue, paint and other liquids in the product process to the precise position of each product, which can be used to achieve dots, lines, circles or arcs.

Friday, November 11, 2022

Auto Rubber Parts Rubber Slippers Logo Making Machinery

Many mobile phone silicone cases you have seen have very beautiful patterns, so how did these patterns come from? Our machines will show you the professional production process. Also we can make earphone cases, keychains, car chains, 3D colorful dolls, trademark gifts, bracelet, sealing ring, various silicone electronic accessories, etc.

Our products also have Dispensing Machines, which are also called glue applicators, glue dispensers, glue machines, glue filling machines, etc., which are specially designed to control fluids; there are also PVC Machines, PVC printing machines, also known as universal flatbed printers. , plastic printing machines, etc.; there are also Silicone Machines, silicone injection molding machines, also known as silicone machines, strictly speaking, silicone injection molding machines; and Kpu Shoes Machines, an automated equipment specially tailored for the uppers of sports shoes; There are also Silicone Label Embossing Machines, which emboss and emboss the labels of silicone products; and CNC Machines tools, which are mechatronics processing equipment with high technology intensity and automation. If you want to know more, welcome to consult us, we will serve you wholeheartedly!

The advantage of silicone heat pressing machine production :

1.Product design unique, diverse styles, color and diverse;

2.Unique self-adhesive smooth surface, non-slip stability, bright color, very decorative;

3.Health and environmental protection, no smell, shock, mildew, sunscreen;

4.Elegant and beautiful, soft and comfortable, free to place, can be regular and physical contact;

5.Sound insulation, easy cutting laying, easy to replace, easy to clean;

6.Good resilience, high tear strength, good flatness, high temperature resistance;

7.Environmental non-toxic, wear-resistant anti-aging, anti-aging, corrosion resistance, durable.

Our service:

1.According to your products, our engineer can introduce the suitable production line for you.

2. You will get factory price.

3. You will get durable quality of machine and most professional service.

4. You visiting to our factory for checking or training is warmly welcome

Our company:

Dongguan Jinyu Automation Equipment Co.,Ltd. is founded in 2000, located in xiangdong industrial area, mainly dealing with silicone, pvc trademarks gifts making equipment, in a short few years, from guangdong pearl river delta to whole coastal area of China, jinyu equipment is all over this industrial, jinyu got the industry's highly recognized. As to reduce the environmental damage,we found silicone industrial, it is environment protection an no harm to human, it is the best choose.

Jinyu researched and developed full automatic dispensing machine, special silicone&rubber dropping ,full automatic vulcanizing machine,is the best foundation of the industrial,jinyu equipment huve the fearures of labors saving saving electricity, saving management .Jinyu company sincerly look forward to the visiting of all the regular and new customers,Let is develop together.

In 2000,founded pvc(plastic dropping)trademark equipment.

In 2002,developed silica gai(silicone)trademark forming machine.

In 2004,researched and developed hydraulic machine 30T,50T,63T,100T.

In 2006,researched and developed full automatic dispensing(dropping)equipment.

In 2008,researched and developed KPU shoes material making machine.

In 2010,researched and developed Full automatic production line.

In 2017,developed automatic(silicone and PVC) production line.

In 2018, developed silicone in-mold transfer trademark.

In 2019, R&D smart oven.

In 2020, research and development of visual dispensing machine.

In 2021, built a new factory three times larger than before.

In 2022, R&D universal mold base.

Our packaging:

We use wooden box packaging, a total of three layers. The first layer is a plastic film, the second layer is foam paper, and finally sealed with a wooden box. This way to ensure that the machine's sealing

FAQ

1. Q:Can you provide technical support?

A: Selection to provide comprehensive technical support, and technical training.

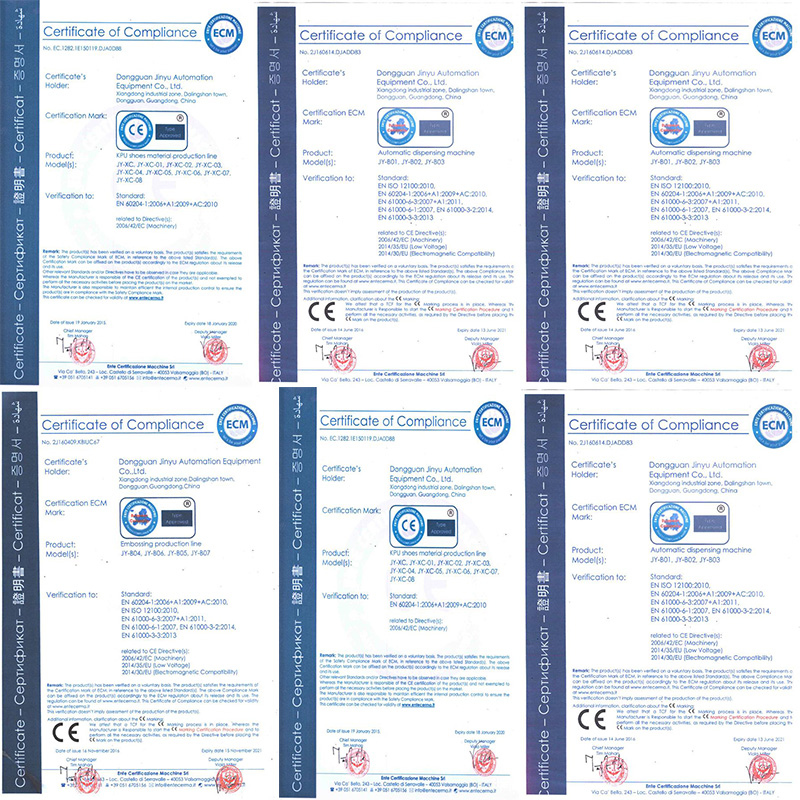

2. Q:Why choose US.?

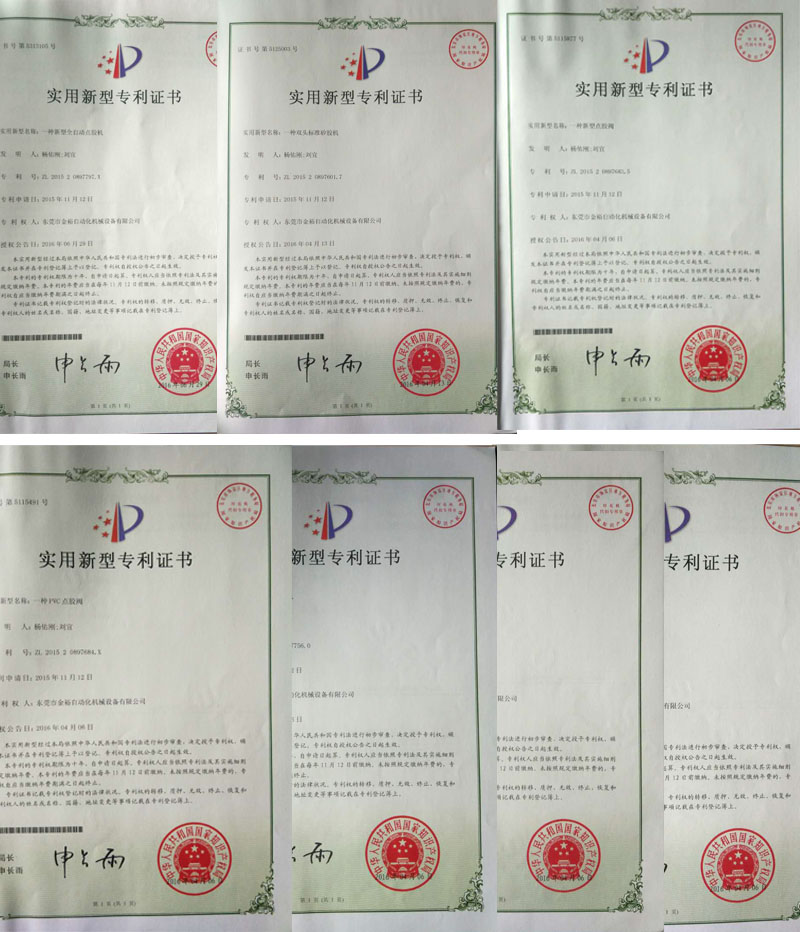

A:Research and development, patent products, company's mission: to help customers improve production efficiency and reduce labor costs

3. Q:Are customized products accepted?

A:Your idea, your choice, we design, we make, to be your factory.

4.Q:If we do not make the craft, will you teach us?

A:Our company will have a professional staff to train you, what do not understand can find our staff to answer

5.Q:What are your strengths?

A:Our machines are developed by our own company, with a number of patents, our machine parts are imported. Machine shape are cast iron structure, precision and permanent deformation.

6.Q:Do you have a warranty if the machine breaks?

A:The quality of our machines is absolutely guaranteed, and there will be no big problems.Most of them will wear out after a long time. We will send the parts and then you will install them

If anything we can do for you, please feel free to contact me!

Wednesday, November 9, 2022

Automatic Garment Rubber Stamp Making Machine

This machine is suitable for pressing various 3d embossing garment products, such as pressing rubber and silicone, and also suitable for sheet or fabric products. The stroke limit adjuster can be adjusted according to the pressed material and the thickness of the mold. It has two stations, independently controlled respectively, can be operated individually or at the same time.

Our equipment also have Dispensing Machines, which are also called glue applicators, glue dispensers, glue machines, glue filling machines, etc., which are specially designed to control fluids; there are also PVC Machines, PVC printing machines, also known as universal flatbed printers. , plastic printing machines, etc.; there are also Silicone Machines, silicone injection molding machines, also known as silicone machines, strictly speaking, silicone injection molding machines; and Kpu Shoes Machines, an automated equipment specially tailored for the uppers of sports shoes; There are also Silicone Label Embossing Machines, which emboss and emboss the labels of silicone products; and CNC Machines tools, which are mechatronics processing equipment with high technology intensity and automation. If you want to know more, welcome to consult us, we will serve you wholeheartedly!

Main Features:

1. Three-axes linkage, support high-speed continuous interpolating of any 3D curve, the speed reaches 999 mm/s.

2. High-speed ladder-shaped acceleration and deceleration, handle the continuo speed based on speed forecasting technology.

3. Repeat positioning control precision can reach 0.5 pulse.

High efficiency procession control:

1. Cooperating high speed movement with the sync glue head and double-sided cycle file procession. you can make the best use of the machine.

2. Choose the file with the shortcut button, can realize compels multiple dispensing procession.

Perfect programming support:

1. Humanized software design idea, easy for study and use.

2. Excellent compatibility, support many design software(including JD paint, Auto CAD, Coreidraw) and various file form-wt which generated. In addition, it also support scanning and teaching programming, without and limit on the graphic track planning.

3. Fast parameter setting and debugging, connection with PC, can amend the graphic immediately, and run it right now.

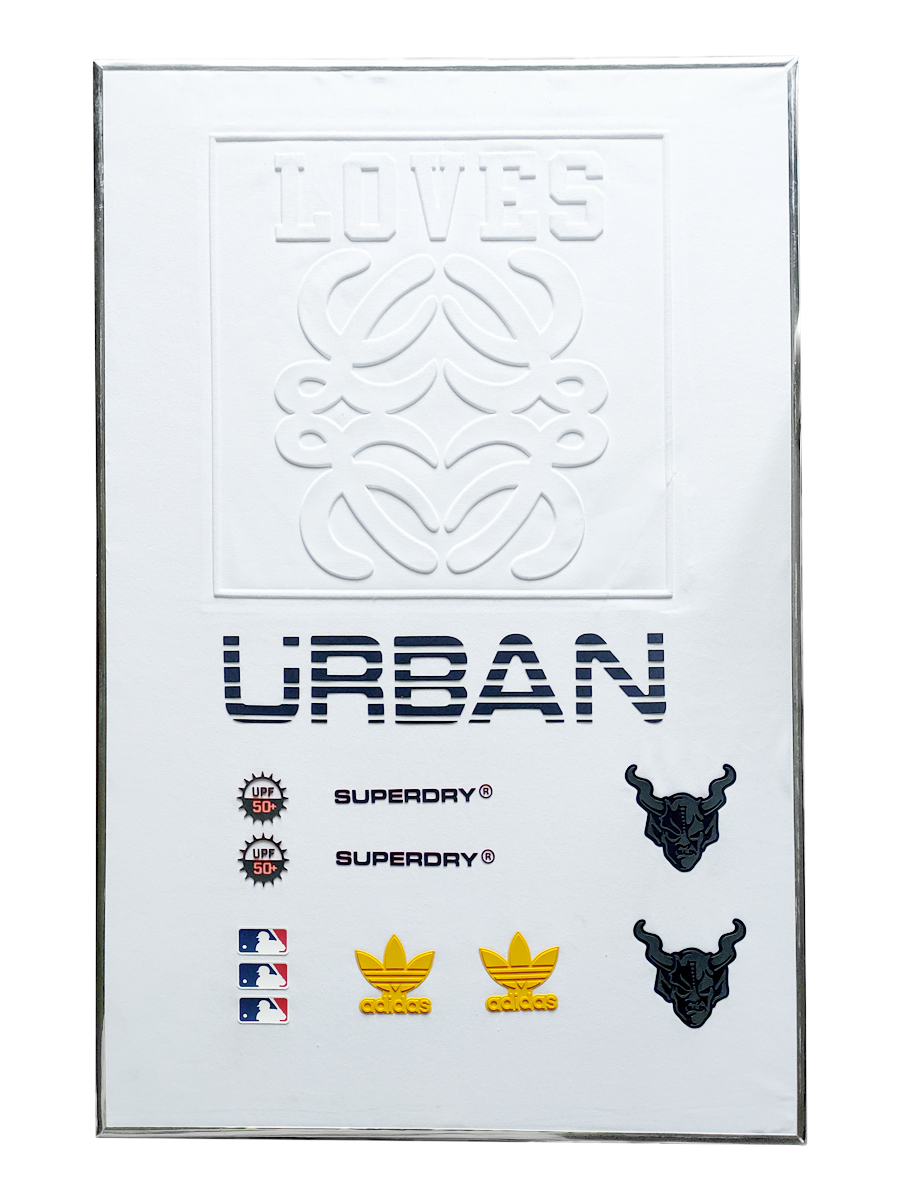

Applications

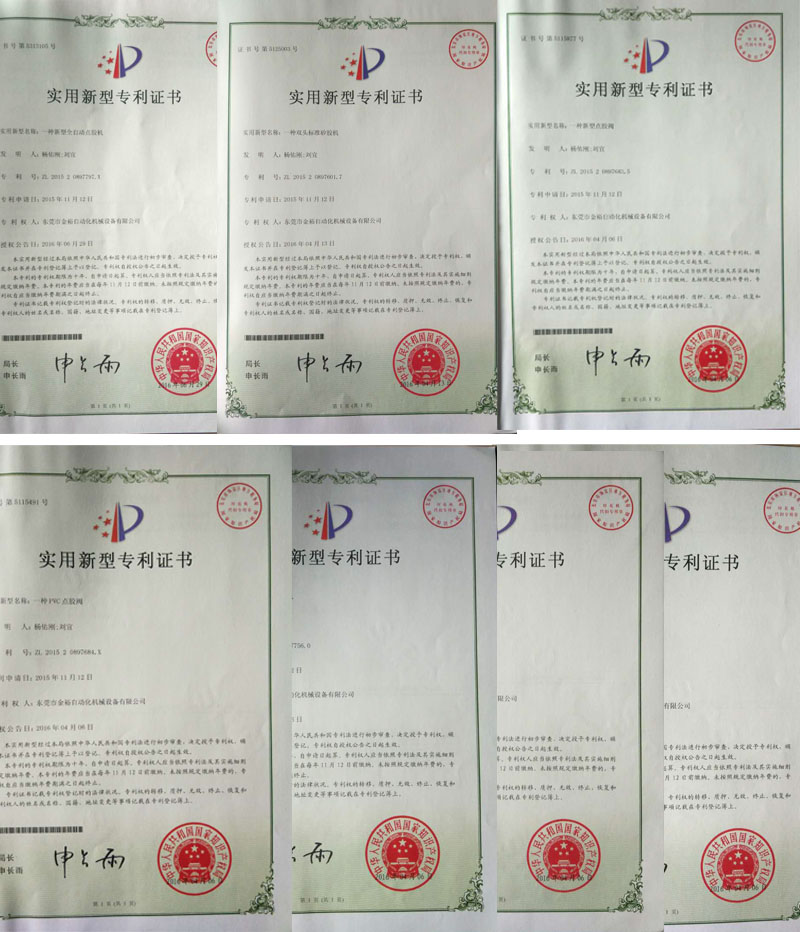

certificate:

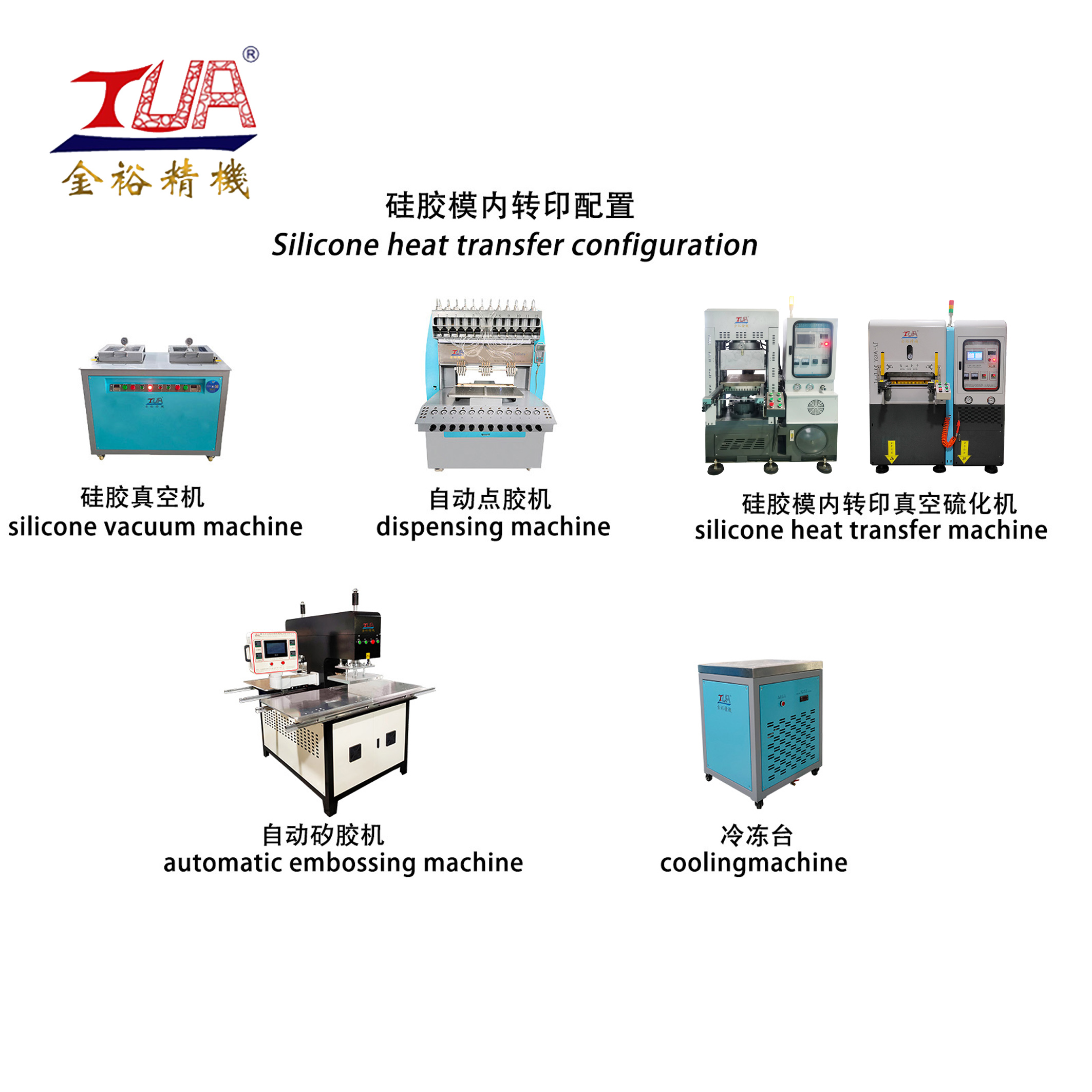

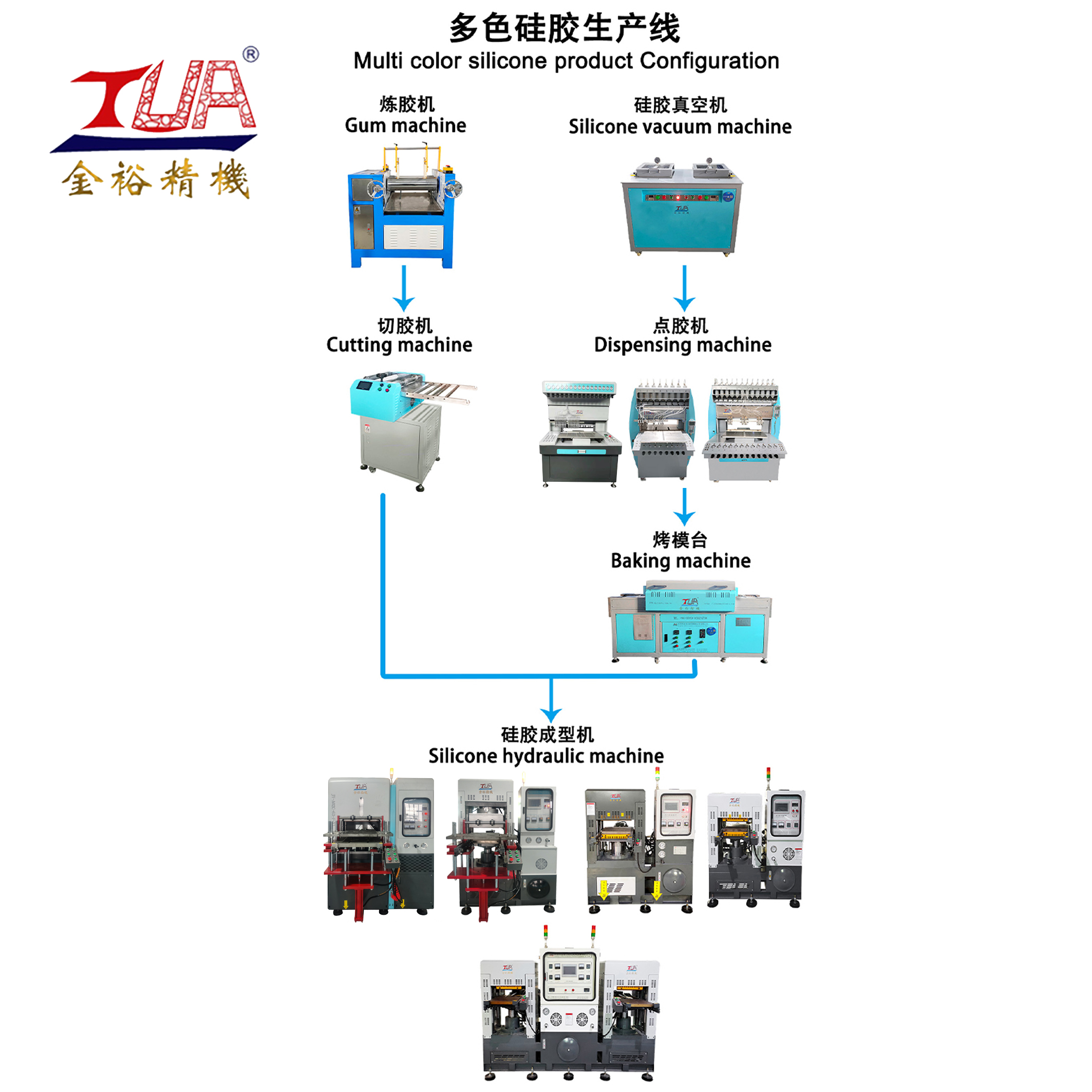

Production Line:

Our Servers:

1.We offer technology guidance. clients can go to our factory to learn how to operate the machine ,and our engineer can go to clients' factory to teach clients, and design the style of the products.

2. We can offer all the things you need in the processing, like: the material, mold, machine, technology.

3. According to your products, our engineer can introduce the suitable production line for you.After-sale service:

1. Warranty: 1 year free and life long maintenance.

2. We offer technology guidance. clients can go to our factory to learn how to operate the machine ,and our engineer can go to clients' factory to teach clients, and design the style of the products.

3. We can offer all the things you need in the processing, like: the material, mold, machine, technology.

We have a workshop in our factory?which keep producing the?products, welcome sincerely customer come to visit and enhance your confidence.

making samples provide:

if you have mould, we can make samples for you.

Packaging:

We use wooden box packaging, a total of three layers. The first layer is a plastic film, the second layer is foam paper, and finally sealed with a wooden box. This way to ensure that the machine's sealing

Dongguan Jinyu Automation Equipment Co.,Ltd. is founded in 2000, located in xiangdong industrial area, mainly dealing with silicone, pvc trademarks gifts making equipment, in a short few years, from guangdong pearl river delta to whole coastal area of China, jinyu equipment is all over this industrial, jinyu got the industry's highly recognized. As to reduce the environmental damage,we found silicone industrial, it is environment protection an no harm to human, it is the best choose.

Jinyu researched and developed full automatic dispensing machine, special silicone&rubber dropping ,full automatic vulcanizing machine,is the best foundation of the industrial,jinyu equipment huve the fearures of labors saving saving electricity, saving management .Jinyu company sincerly look forward to the visiting of all the regular and new customers,Let is develop together.

In 2000,founded pvc(plastic dropping)trademark equipment.

In 2002,developed silica gai(silicone)trademark forming machine.

In 2004,researched and developed hydraulic machine 30T,50T,63T,100T.

In 2006,researched and developed full automatic dispensing(dropping)equipment.

In 2008,researched and developed KPU shoes material making machine.

In 2010,researched and developed Full automatic production line.

In 2017,developed automatic(silicone and PVC) production line.

In 2018, developed silicone in-mold transfer trademark.

In 2019, R&D smart oven.

In 2020, research and development of visual dispensing machine.

In 2021, built a new factory three times larger than before.

In 2022, R&D universal mold base.

FAQ:

1. Q:Can you provide technical support?

A: Selection to provide comprehensive technical support, and technical training.

2. Q:Why choose Jinyu Automation Equipment Co.,Ltd.?

Research and development, patent products, company's mission: to help customers improve production efficiency and reduce labor costs

3. Q:Are customized products accepted?

A:Your idea, your choice, we design, we maketo be your factory.

4.Q:If we do not make the craft, will you teach us?

A:Our company will have a professional staff to train you, what do not understand can find our staff to answer

5.Q:What are your strengths?

A:Our machines are developed by our own company, with a number of patents, our machine parts are imported. Machine shape are cast iron structure, precision and permanent deformation.

6.Q:Do you have a warranty if the machine breaks?

A:The quality of our machines is absolutely guaranteed, and there will be no big problems.Most of them will wear out after a long time. We will send the parts and then you will install them

If anything we can do for you, please feel free to contact me!

Saturday, November 5, 2022

Heat Press Machine Make Leather Embossing For Sale

Product Advantage

1.With 2 working station, have the high output.

2. With hydraulic press, not the air press, it's more stable.

3. With preheating functions, improve the work efficiency.

4. Intelligent PID control output, it's economic and energy-saving.

The silicone label embossing machine is for producing the silicone label on garment clothes and leather, also using for fabric embossing. We sale our machine to all over the world, like Portugal, Italy, USA, Mexico, India, Thailand, Indonesia and so on, with the CE certificate. And we have agents at many country, so don't worry about the after-sale service.

seaworthy wooden case.

Seaworthy wooden case packing,To be packed by new strong wooden cases suitable for long distance ocean transportation and well protected against dampness, moisture, shock, rust and rough handling.

1.Q: Are you a factory or trading company?

A: We are a factory.

2.Q: Where is your factory located?

A:The town of Chashan, dongguan city, guangdong province, China

3. Q: How about quality control in your factory?

A: focuses on quality,quality control from beginning to the end. Every piece of goods is tested strictly before packing and delivery.

4.Q: How about guarantee ?

A: One year guarantee.

5.Q:Can you provide technical support?

A: Selection to provide comprehensive technical support, and technical training.

6. Q:Why choose Jinyu Automation Equipment Co.,Ltd.?

Research and development, patent products, company's mission: to help customers improve production efficiency and reduce labor costs

Wednesday, November 2, 2022

High yield new automatic best quality machine to make silicone and pvc products rubber label patch

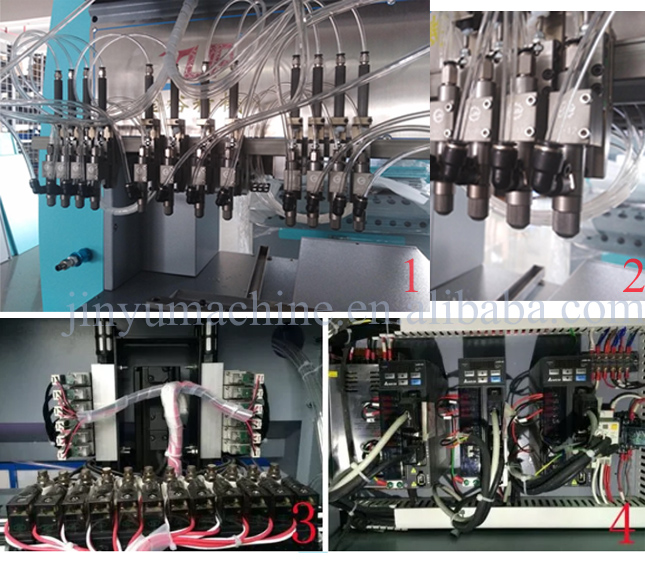

This machine used in both silicone and PVC material production. The worktable has a heating function, which effectively promotes the flow performance of the product. Linear guide rail is used to control the left and right sliding of glue dispensing, stable glue application, and no glue leakage phenomenon.

Our products also have Dispensing Machines, which are also called glue applicators, glue dispensers, glue machines, glue filling machines, etc., which are specially designed to control fluids; there are also PVC Machines, PVC printing machines, also known as universal flatbed printers. , plastic printing machines, etc.; there are also Silicone Machines, silicone injection molding machines, also known as silicone machines, strictly speaking, silicone injection molding machines; and Kpu Shoes Machines, an automated equipment specially tailored for the uppers of sports shoes; There are also Silicone Label Embossing Machines, which emboss and emboss the labels of silicone products; and CNC Machines tools, which are mechatronics processing equipment with high technology intensity and automation. If you want to know more, welcome to consult us, we will serve you wholeheartedly!

Main Features:

1. Three-axes linkage, support high-speed continuous interpolating of any 3D curve, the speed reaches 999 mm/s.

2. High-speed ladder-shaped acceleration and deceleration, handle the continuo speed based on speed forecasting technology.

3. Repeat positioning control precision can reach 0.5 pulse.

High efficiency procession control:

1. Cooperating high speed movement with the sync glue head and double-sided cycle file procession. you can make the best use of the machine.

2. Choose the file with the shortcut button, can realize compels multiple dispensing procession.

Perfect programming support:

1. Humanized software design idea, easy for study and use.

2. Excellent compatibility, support many design software(including JD paint, Auto CAD, Coreidraw) and various file form-wt which generated. In addition, it also support scanning and teaching programming, without and limit on the graphic track planning.

3. Fast parameter setting and debugging, connection with PC, can amend the graphic immediately, and run it right now.

Applications

certificate:

Production Line:

Our Servers:

1.We offer technology guidance. clients can go to our factory to learn how to operate the machine ,and our engineer can go to clients' factory to teach clients, and design the style of the products.

2. We can offer all the things you need in the processing, like: the material, mold, machine, technology.

3. According to your products, our engineer can introduce the suitable production line for you.After-sale service:

1. Warranty: 1 year free and life long maintenance.

2. We offer technology guidance. clients can go to our factory to learn how to operate the machine ,and our engineer can go to clients' factory to teach clients, and design the style of the products.

3. We can offer all the things you need in the processing, like: the material, mold, machine, technology.

We have a workshop in our factory?which keep producing the?products, welcome sincerely customer come to visit and enhance your confidence.

making samples provide:

if you have mould, we can make samples for you.

Packaging:

We use wooden box packaging, a total of three layers. The first layer is a plastic film, the second layer is foam paper, and finally sealed with a wooden box. This way to ensure that the machine's sealing

Dongguan Jinyu Automation Equipment Co.,Ltd. is founded in 2000, located in xiangdong industrial area, mainly dealing with silicone, pvc trademarks gifts making equipment, in a short few years, from guangdong pearl river delta to whole coastal area of China, jinyu equipment is all over this industrial, jinyu got the industry's highly recognized. As to reduce the environmental damage,we found silicone industrial, it is environment protection an no harm to human, it is the best choose.

Jinyu researched and developed full automatic dispensing machine, special silicone&rubber dropping ,full automatic vulcanizing machine,is the best foundation of the industrial,jinyu equipment huve the fearures of labors saving saving electricity, saving management .Jinyu company sincerly look forward to the visiting of all the regular and new customers,Let is develop together.

In 2000,founded pvc(plastic dropping)trademark equipment.

In 2002,developed silica gai(silicone)trademark forming machine.

In 2004,researched and developed hydraulic machine 30T,50T,63T,100T.

In 2006,researched and developed full automatic dispensing(dropping)equipment.

In 2008,researched and developed KPU shoes material making machine.

In 2010,researched and developed Full automatic production line.

In 2017,developed automatic(silicone and PVC) production line.

In 2018, developed silicone in-mold transfer trademark.

In 2019, R&D smart oven.

In 2020, research and development of visual dispensing machine.

In 2021, built a new factory three times larger than before.

In 2022, R&D universal mold base.

FAQ:

1. Q:Can you provide technical support?

A: Selection to provide comprehensive technical support, and technical training.

2. Q:Why choose Jinyu Automation Equipment Co.,Ltd.?

Research and development, patent products, company's mission: to help customers improve production efficiency and reduce labor costs

3. Q:Are customized products accepted?

A:Your idea, your choice, we design, we make to be your factory.

4.Q:If we do not make the craft, will you teach us?

A:Our company will have a professional staff to train you, what do not understand can find our staff to answer

5.Q:What are your strengths?

A:Our machines are developed by our own company, with a number of patents, our machine parts are imported. Machine shape are cast iron structure, precision and permanent deformation.

6.Q:Do you have a warranty if the machine breaks?

A:The quality of our machines is absolutely guaranteed, and there will be no big problems.Most of them will wear out after a long time. We will send the parts and then you will install them

If anything we can do for you, please feel free to contact me!