kpu upper shoes cover making machine can make all kind of KPU shoes upper, High production efficiency, good quality, long service life

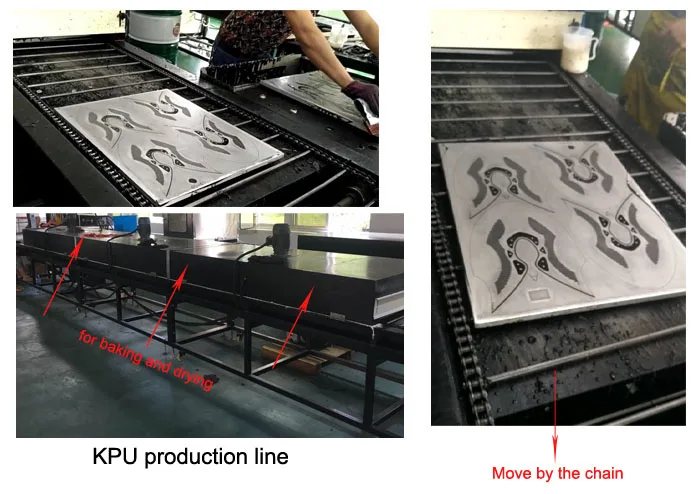

production line

Product Advantage

kpu upper shoes making machine

1. Adopt the world advanced SOLIDEWORK3D software and finite element analysis of mechanical design, the optimum design is integrally molded high rigidity, precise structure, long service life.

2. Heating plate adopt deep hole processing, and after carburizing,after grinding nit-riding, using the principle of heat, get the high precision, and the optimal design with average temperature, HRC50-55 hardness, long time wear-resisting, Not easy to be out of shape and it has high plane precision.

3. Using the technology of planar pressure correction, the maximum pressure(200KG) nut leveling device,the highest plane precision can reach 0.05 MM

our factory

1.Our company has its own factory, the staff have many years of production engineering technical experience, the overall production strength, the machine quality is high

2.At present, our r&d department often develops new machines according to market changes. Strive for the market for customers

3.High production speed and guarantee

4.Independent research and development, multiple patents

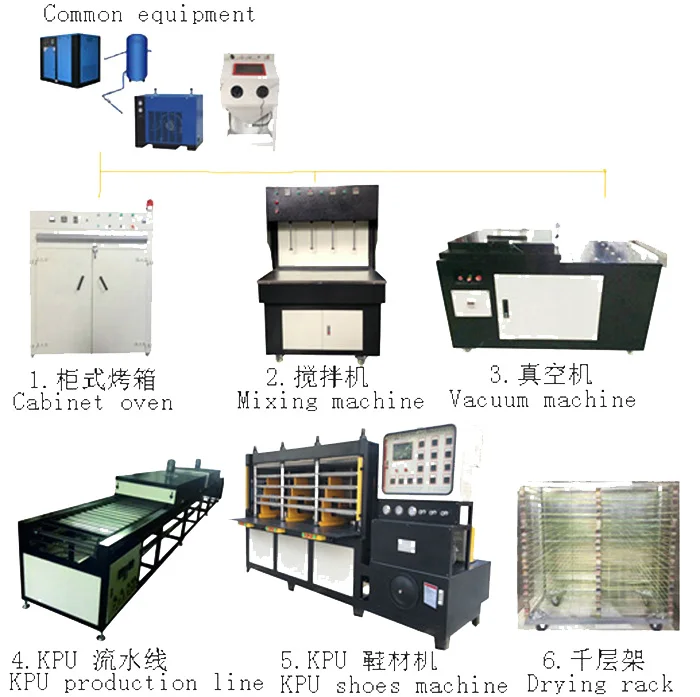

5.Be flexible in order to see specific products.The equipment needed for Making Shoes Upper.Making Shoes Upper equipment for Shoes Upper used shoe upper equipment

2.At present, our r&d department often develops new machines according to market changes. Strive for the market for customers

3.High production speed and guarantee

4.Independent research and development, multiple patents

5.Be flexible in order to see specific products.The equipment needed for Making Shoes Upper.Making Shoes Upper equipment for Shoes Upper used shoe upper equipment

Package:

seaworthy wooden case.

1. We offer the technical guidance. Clients can learn how to operate the machine at our factory, and our engineer can go to clients' factory to teach how to operate our machine, and design the style of the products.

2. We can offer all the things you need in the processing, like: the mold, material, machine, technology.

3. According to yur products,our engineer can introduce the suitable program for you.

1. We offer the technical guidance. Clients can learn how to operate the machine at our factory, and our engineer can go to clients' factory to teach how to operate our machine, and design the style of the products.

2. We can offer all the things you need in the processing, like: the mold, material, machine, technology.

3. According to yur products,our engineer can introduce the suitable program for you.

Our Services

1. We offer the technical guidance. Clients can learn how to operate the machine at our factory, and our engineer can go to clients' factory to teach how to operate our machine, and design the style of the products.

2. We can offer all the things you need in the processing, like: the mold, material, machine, technology.

3. According to your products,our engineer can introduce the suitable program for you.

2. We can offer all the things you need in the processing, like: the mold, material, machine, technology.

3. According to your products,our engineer can introduce the suitable program for you.

No comments:

Post a Comment